We sell the TPE/TPV/TPU, the cheapest in the world !

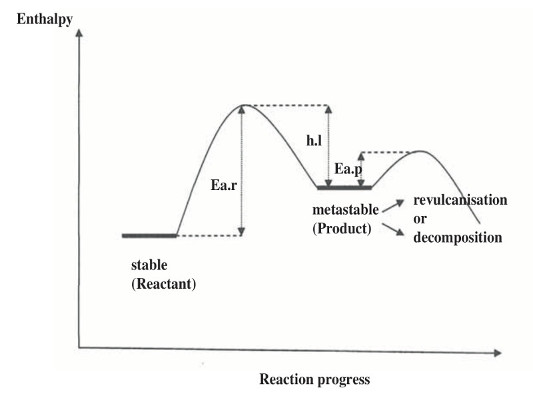

Basing our observations on phenomena on vulcanized rubbers and plastics within industries since 1999, we have presented the theory of metactivation® / Metastable State in polymers through French patents (year 2009), European, American and Korean (in processing) According to the theory of metactivation®, the metastable state is between the stable and unstable state: A stable state (with minimum entropy) naturally evolves to the unstable state (with maximum entropy).

In the polymer field, a cross-linked/vulcanized rubber is stable for very long time (at minimum entropy). On the other hand, a virgin rubber is, in nature, in unstable condition/state with maximum entropy.

However, the inventor noted, for the first time in the world, that there is new material which comes from a crosslinked rubber having undergone a mechanical operation, which behaves neither like the original crosslinked rubber (so, stable with a minimum entropy), nor a virgin rubber (so, unstable with a maximum entropy). This new polymeric material is named 'metastable matter '. Its physicochemical characteristics are, for the first of the world, defined in the patents of the inventor.

In principle, a system with a stable State of minimum entropy goes naturally with time to a State of maximum entropy (unstable) system. It is a natural process on Earth.

Nevertheless, the operation which allows the transfer of the State of minimum entropy (a crosslinked/vulcanized polymer, for example) to a metastable state (a metastable polymer), is artificial and named "metactivation®" by the inventor: Metactivation® is an industrially applied acceleration process, for example, in order to transform a crosslinked polymer into metastalised/metastable polymer. This metastable/metastabilised polymer remains thermodynamically unchanged for years in nature at a temperature of 25 ° C.

Under certain conditions, this metastable polymer is reactive to chemical products at various temperatures, etc. --- so as to be crosslinked/polymerized or decomposed. In all, as all kinds of polymers, this metastable polymer has also his own way of reaction which shows us how to use it.

The inventor uses an economic and effective process of metactivation® on already-crosslinked polymers, and, after, in mixing/compounding this metastable polymers, manufactures new articles in TPE, TPV, TPUrethane, modified bitumen, rubber compounds, etc. - which are industrially and economically interesting.

PaDA® a kind of polymer-compound

is a kind of polymer-compound in fine powder form which carbon black and additives are already in, then, crosslinkable materials.

These polymer products are produced through our patented technology Metactivation®.

A) Fine powder rubber compounds : classified HS code, 40 05 99 90

B) Powder plastic compound : classified HS code, 39 16 10 00

C) TPE/TPV black granules :

A new generation of compounds / masterbatches several compositions developed to enable you to make new types of compounds in TPE, TPV, TPUrethane, NR, SBR, EPDM, Bitume, Epoxy, etc...

Advantages :

Our PaDA® is patent material in France, Europe, USA and Korea (in processing).

Our metactivation® technology is patent process/machine in France.

Avec nos PaDA®